An Unbiased View of Aws Cwi

An Unbiased View of Aws Cwi

Blog Article

Get This Report on Aws Cwi

Table of ContentsThe Of Aws CwiThings about Aws CwiSome Of Aws CwiThe Best Strategy To Use For Aws CwiFascination About Aws Cwi

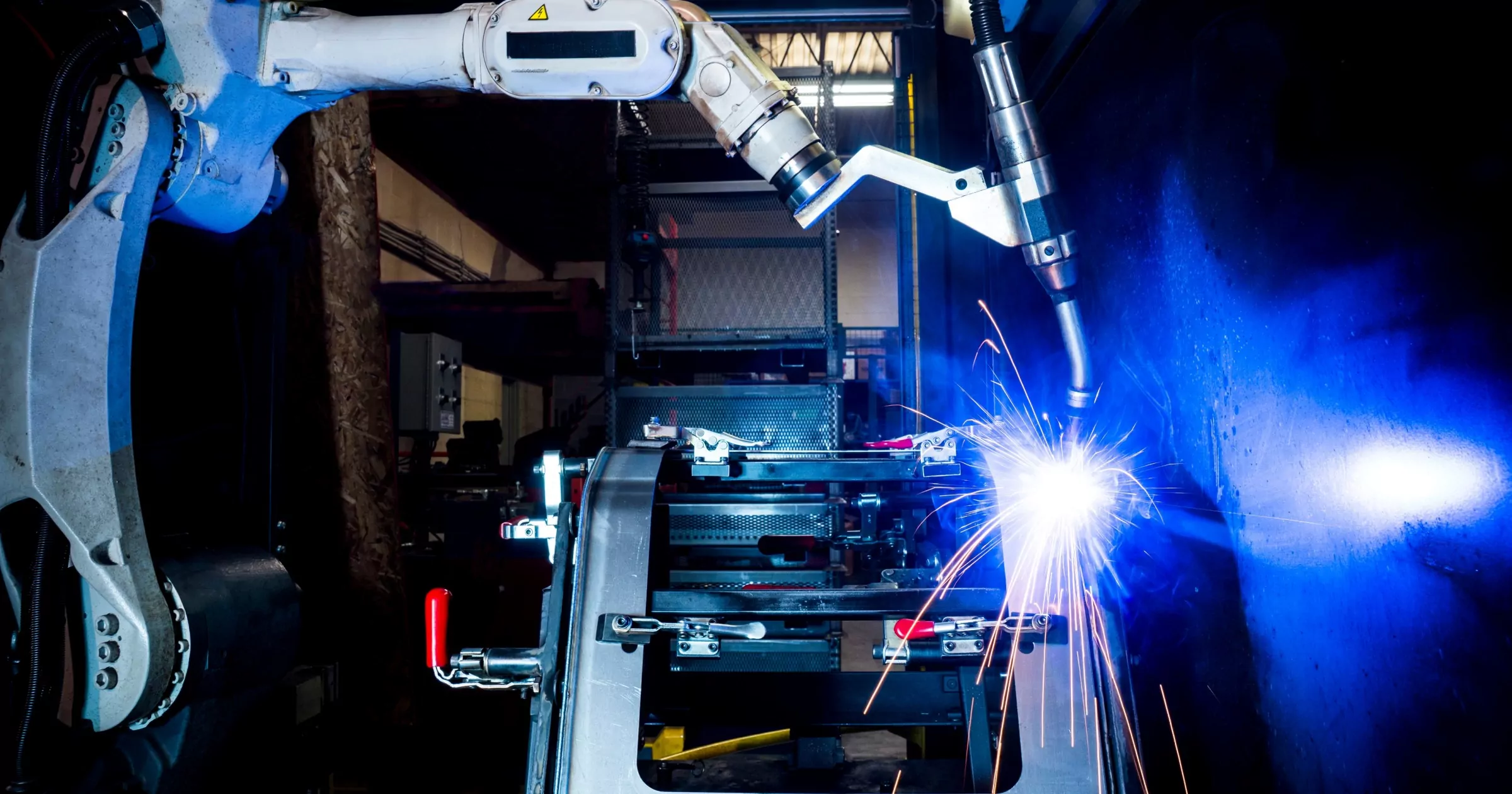

Have you ever before considered a career as a welding examiner? A welding assessment qualification can be advantageous for a variety of factors. Keep reading to read more and register for CWI programs with Real Educational Solutions, Inc. today! A welding evaluation certification is not only a wonderful accomplishment, it confirms your capabilities in the welding industry.

Becoming a Qualified Welding Examiner reveals your dedication to expanding within the welding sector. This accreditation is one that must not and will certainly not be forgotten! As a CWI, you'll have the ability to make the most of a number of various opportunities among market experts.

As you may know, welding is one of the most complicated solutions within the steel fabrication market (https://www.figma.com/design/FRiLRXmmMFRuQGEzI6ECVz/Untitled?node-id=0-1&t=qzFSvhIwQu3JIjUn-1). The outcome of every welding project is extremely dependent upon individual welder ability.

Some Known Details About Aws Cwi

There's no question that CWIs help to promote better levels of uniformity and high quality to the welding divisions they oversee. This post supplies a quick introduction of the primary advantages of collaborating with a steel manufacture company that utilizes certified weld inspectors. It's not shocking that most high-profile industries will certainly need you to work with certified welding inspectors to oversee welding.

Qualified welding examiners have years of experience and thus, they understand the nuances of compliance with welding codes. Following the welding procedure, CWIs can conduct a series of test to inspect the high quality of a weld, consisting of aesthetic assessment, warm treatment and a hydrostatic examination. Certified Welding Inspection. They can additionally make the appropriate adjustments to the pre-weld preparation and the in-weld treatments as needed

An internal licensed welding assessor will be able to assure that your task is tailored to all the requirements of pertinent welding codes, ensuring its top quality. Welding assessors can assess welding treatment specs, building and welding strategies, tools calibration and welding products. A welding examiners ability to provide welding treatment specs supplies the metal fabrication business a substantial side of the competitors, permitting fabricators to design welds that ideal suit specific parts, instead of making use of reliable welds.

7 Simple Techniques For Aws Cwi

As formerly pointed out, a CWI is not just accountable fore creating the procedures for the weld, but additionally the quality-check screening procedures. https://papaly.com/categories/share?id=273a3f2a2b4b468095e296e4b0aec364. Past that, welding examiners work to make certain that equipment is effectively prepped for the task which welders have the ability to finish their welds with capability (AWS CWI). A certified welding inspector will certainly have had several years of experience, which a steel construction business can take advantage of to make certain excellent outcomes for all construction projects that involve welding

This is why it's critical to locate a welding business with a knowledgeable and very educated in-house qualified welding inspector on staff. CAMM metals is such a service, so contact us today if you have an approaching task that calls for quality customized welding! It's clear that a personalized metal fabrication supplier with in-house CWIs has committed to buying the high quality of its welds.

Some markets require CWIs to be included in the manufacturing of components. Ultimately, CWIs assume quite a bit of responsibility, yet their experience receives navigate here the final item. Right Here at CAMM Metals, after the welding portion of the job is total, we provide lots of in-house services. These solutions include weld examination with color penetrant, acid cleansing and sprucing up of stainless steel welds.

For those clients who call for certified welds, we can license our welds to AWS D1.1 & AWS D1.6.

Aws Cwi - Truths

It's essential to keep in mind that lots of companies don't constantly require welders to be accredited. Some only ask that work applicants pass a welder performance certification prior to hiring them. In this scenario, those who pass the examination would certainly be considered "certified welders," not "accredited welders." The major difference is that qualified welders have actually composed documents of their examination outcomes and their efficiency is constantly kept an eye on with regular examination( s) being component of the performance record for each welder.

Before taking the examination all PFS welders are educated, if called for, in the real welding procedure that they will be utilizing and they will certainly need to have a working knowledge of the welding devices, welding palatable and the product to be bonded. Successfully passing one examination will permit the welder to work with several kinds of constructions but will not permit him to work on all types of construction as there are qualification ranges enforced for each and every examination configuration.

Important variables include yet are not limited to material type, consumable type, product density and welding position. and so on. After the welder has actually finished his examination plate or pipeline the weld is examined using the complying with NDE procedures: Aesthetic Examination X-Ray Liquid Penetrant Screening Sometimes, the weld is additionally destructively tested.

Aws Cwi Things To Know Before You Buy

PFS achieves this using a continuity record that information all welds that a welder makes. If a welder does not make use of the welding process in a 6-month period, after that they shall be requalified because procedure. The advantages to making use of a certification system are lots of yet the major benefits are: It validates the ability of an individual to carry out according to a certified welding treatment spec (WPS) to create an excellent weld.

Report this page